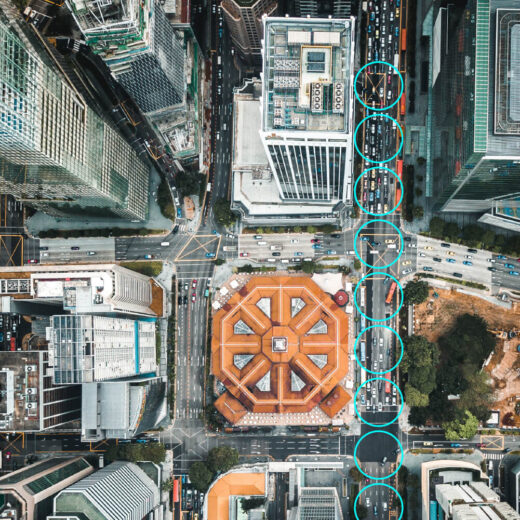

Intelligent Technician Dispatching

Customer

Major Swiss Chemical company

Problem

- Technician dispatching not as efficient as possible

- Currently used algorithms were too slow and did not allow for quick reaction, recalculation of the routes/dispatching of the technicians

Solution

- Train a reinforcement learning model to achieve same or better accuracy more quickly at a lower cost

Impact

- Improved Technician efficiency, reaching more customers and resolving more issues per technician per day

AI Sales Forecasting

Customer

Major Swiss Chemical company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Problem

- The customer was looking to automate the sales forecasting process which to date was performed in a manual way, making it cumbersome and error prone

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

Supply Chain Control Tower

Customer

International Reseller

Building a tool to provide a 360° view over the whole supply chain, coupled with an alerting system when a certain material is reaching low stock levels

Challenge

- Recurrent struggle with materials being out of stock resulting in significant loss in sales

Solution

- Built application enabling users to see the whole supply chain, either globally or per material

- Implemented an alerting system that reports when a certain stock level is low and will soon need replenishment

Impact

- Reduction of average out-of stock levels at a given point in time by about 50%

- Lowered loss of turnover due to materials being out of stock

AI Supply Chain Forecasting

Customer

Major Swiss Chemical company

Problem

- The need to improve the current forecasting process (raw-materials, finished goods and sales)

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

Airlines Data Platform Onboarding

Customer

Airplane producer

Onboarding airlines across 3 continents on a central data analytics platform with activities such as training and enablement of new users

Challenge

- Need for airlines’ data scientists and executives to explore data independently and be able to implement new use cases on their own

Solution

- Prepared educational material, such as presentations and project examples

- Gave lectures and conducted workshops to train new users to use the Foundry platform

Impact

- Enabled new users to acquire new skills allowing them to implement future use cases and to analyse data independently

Aircrafts Predictive Maintenance

Customer

Airplane producer

Implementing a data platform to centralise maintenance data from hundreds of airlines and enable predictive maintenance models

Challenge

- Integrate data from 100s of airlines on a single platform

- Reduce or eliminate operational interruptions and minimise the number of aircrafts immobilised due to unforeseen maintenance needs

Solution

- Integrated sensor data and telemetry into central data lake

- Developed predictive maintenance model outputting the probability of maintenance need in the next 5 flights for each aircraft

Impact

- Notable improvement in speed of problem detection, triaging and resolution

- Enabled feedback loop to aircraft design teams to prevent similar issues from reoccurring