Manufacturing 4.0

Swiss Manufacturer

Problem

- Customer struggled with hard to detect issues in manufacturing line that slowed down production

Solution

- Conducted a data driven production line optimization

- Created a real time monitoring system of the factory with anomaly detection algorithms and alerting system built in

Impact

- 15% increase in production speed (throughput)

- 8x ROI

Sales Forecasting in Supply Chain

Global Retail Manufacturer

Developing a forecasting platform for model benchmarking, tuning and selection resulting in more accurate, and efficient retail sales forecasting as well as empowerment to define new use cases.

Challenge

- Client needs more accurate and efficient furniture sales forecasts for supply chain planning

- +10 Mio different store products make it difficult to find optimal forecasting method

- Client lacks expertise in forecasting

Solution

- Built a forecasting platform around Darts to efficiently benchmark, tune, and select forecasting models on any use case.

- Trained models on +10k different products to globally learn information

- Coached client on forecasting fundamentals and best practices

Business Impact

- Best model outperformed existing solution in accuracy and efficiency

- Client can now more optimally plan supply chain and define new forecasting use cases through the platform.

- Client uses platform to define new forecasting use cases

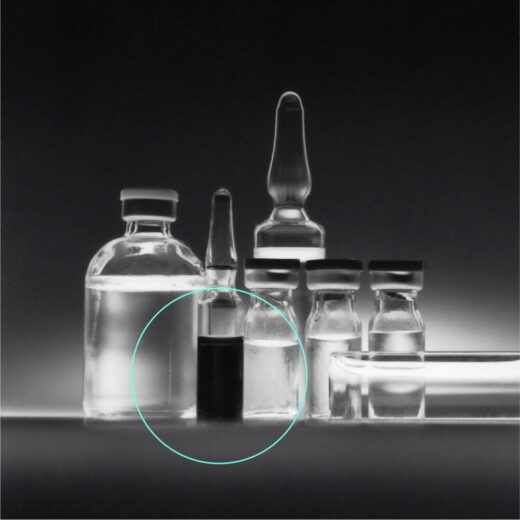

Workshop – Data-driven Strategy

Multinational Life Sciences Company

Conducted a data & analytics strategy workshop to identify the main opportunities and select an optimal implementation strategy for initial use cases

Problem

- Interest in developing data & analytics capabilities but lack clear approach and direction to select and implement use cases

- Limited knowledge about AI and its opportunities

- Unclear view of the data & analytics implementation strategies available and current best practices

Solution

- Assessed existing IT strategy and highlighted gaps where support of D&A use cases lacked

- Collaboratively identified main D&A opportunities in value chain

- Introduced best practices on defining and implementing a D&A strategy

- Covered multiple implementation strategies and selected best fit

Impact

- Increased awareness about opportunities and limitations of AI in client’s industry

- Gained clear view of main opportunities and pain points in value chain

- Identified a “use case driven” implementation strategy as the best fit for their organisation

Data Science Platform Consulting & Design

Swiss Watchmaker

Provided consulting services for new data science infrastructure and platform selection to allow for more advanced projects in the future

Problem

- Limited storage and computing infrastructure for data science

- Tedious and manual start-up of data science projects

- Lack of governance for AI projects

Solution

- Consulting advice for new data science infrastructure and platform

- Conducted status-quo analysis of the current platform landscape and developed target architectures for both on-premise and PaaS alternatives

Impact

- Helped in gaining a better understanding of future platform alternatives

- Provided insight on how to create a secure and shared environment to host production-ready data science projects

- Established a clear target infrastructure

AI Sales Forecasting

Major Swiss Chemical company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Problem

- The customer was looking to automate the sales forecasting process which to date was performed in a manual way, making it cumbersome and error prone

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

AI Automated Forecasting

Swiss Chemical Company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Challenge

- Needed to accurately forecast sales, raw materials supply and market demand for finished goods

- Existing forecasting methods were labour-intensive and inconsistent

- Models failing to provide accurate, reliable forecasts

Solution

- Created powerful new methods to generate and combine forecasting models

- Developed modern, state-of-the-art forecasting algorithm

- Delivered an automated solution which aggregated data sources and combined forecasting models together to attain higher accuracy

Business Impact

- Reached 97-98% in forecasting accuracy through combination of forecasting model, higher than any single model on its own

- Enabled an optimisation of operations, resulting in monetary and time savings

- Decreased risk of manual errors through forecasting automation

Logistic Base Optimisation

Swiss Chemical Company

Creating custom statistical algorithm to define optimal “logistic bases” for formulas in order to minimize the amount of pouring and reduce costs

Challenge

- Ingredients need to be mixed at certain ratios to create flavours. Some ingredients are pre-mixed into what is called “logistic bases” to reduce the number of pours

- Choice of logistic bases by human expert is becoming harder

- Goal to find optimal logistic bases through an algorithm to increase pouring efficiency

Solution

- Created custom statistical algorithm that incorporates information about the creation process and historical production data

- Solution was however not implemented because deemed too risk to change the whole production process

Business impact

- Theoretically, the new logistic bases created through our algorithm would reduce the number of pours by 10%

- Would lead to a cost reduction after break-even with initial production process change investment

Production Line Optimisation

Swiss Chemical Company

Analysing a production line to improve production speed and anticipate slow-downs resulting in 15% speed-up with a 8x ROI

Challenge

- Perfume production plant efficiency was very variable and production encountered several slow-downs

Solution

- Conducted initial data analysis and discovered that slow-downs were caused by some valves being clogged

- Cleaning the valves lead to overall equipment effectiveness (OEE) improvements

- Built custom application to monitor KPIs in real time and alert operators about undetected issues

Business impact

- Increased production line efficiency and speed

- OEE increased by 8%, speed-up of production by 15%

- 8x return on investment

Process Order Optimisation in Manufacturing Line

Swiss Chemical Company

Defining an mathematically optimal manufacturing sequence order to reduce total production time of perfumes

Challenge

- Manufacturing line produces perfumes by blending ingredients

- Sequence order can be optimised to reduce time and complexity of production

- Goal to compute optimal scheduling to pour ingredients for each blend

- Past factory data was scarce and implementation initially seemed complicated

Solution

- Implemented mathematical optimisation algorithm that defined optimal production sequence to manufacture perfumes

- Simulation to test impact of different optimisation methods compared to what happens in the factory

- Chose “Iterated Greedy” method

Business impact

- Faster manufacturing due to mathematically optimal production sequence

- Approx. 3% improvement in manufacturing speed

- Resulting in 6 digits cost saving figures

AI Supply Chain Forecasting

Major Swiss Chemical company

Problem

- The need to improve the current forecasting process (raw-materials, finished goods and sales)

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

Production line continuous monitoring

Swiss division of a Global Pharma

Problem

- The customer’s production line went through a data driven optimization, the customer wants to ensure the production line maintains the highest possible OEE and wants to add advanced features like automated issue detection & prediction

Solution

- Near real time continuous monitoring system of key production processes with advanced analytics built in (alerting, trend detection, anomaly detection, predictive maintenance)

Impact

- Greater production process visibility

- Quicker time to resolution

- Improved uptime

Production line optimization

Swiss division of Global Pharma

Problem

- Running out of production capacity, significant CapEx investment needed in the new production line to keep up with demand

- Goal: increase the production capacity by 5% via advanced analytics

Solution

- Data integration, AWS platform

- Anomaly detection algorithms

- Data correlations -> insights -> recommendations

Impact

- Trending towards 11% of productivity increase (throughput and yield optimization)

- 15x ROI