Airlines Data Platform Onboarding

Airplane producer

Onboarding airlines across 3 continents on a central data analytics platform with activities such as training and enablement of new users

Challenge

- Need for airlines’ data scientists and executives to explore data independently and be able to implement new use cases on their own

Solution

- Prepared educational material, such as presentations and project examples

- Gave lectures and conducted workshops to train new users to use the Foundry platform

Impact

- Enabled new users to acquire new skills allowing them to implement future use cases and to analyse data independently

Sales Forecasting in Supply Chain

Global Retail Manufacturer

Developing a forecasting platform for model benchmarking, tuning and selection resulting in more accurate, and efficient retail sales forecasting as well as empowerment to define new use cases.

Challenge

- Client needs more accurate and efficient furniture sales forecasts for supply chain planning

- +10 Mio different store products make it difficult to find optimal forecasting method

- Client lacks expertise in forecasting

Solution

- Built a forecasting platform around Darts to efficiently benchmark, tune, and select forecasting models on any use case.

- Trained models on +10k different products to globally learn information

- Coached client on forecasting fundamentals and best practices

Business Impact

- Best model outperformed existing solution in accuracy and efficiency

- Client can now more optimally plan supply chain and define new forecasting use cases through the platform.

- Client uses platform to define new forecasting use cases

Workshop – Data-driven Strategy

Multinational Life Sciences Company

Conducted a data & analytics strategy workshop to identify the main opportunities and select an optimal implementation strategy for initial use cases

Problem

- Interest in developing data & analytics capabilities but lack clear approach and direction to select and implement use cases

- Limited knowledge about AI and its opportunities

- Unclear view of the data & analytics implementation strategies available and current best practices

Solution

- Assessed existing IT strategy and highlighted gaps where support of D&A use cases lacked

- Collaboratively identified main D&A opportunities in value chain

- Introduced best practices on defining and implementing a D&A strategy

- Covered multiple implementation strategies and selected best fit

Impact

- Increased awareness about opportunities and limitations of AI in client’s industry

- Gained clear view of main opportunities and pain points in value chain

- Identified a “use case driven” implementation strategy as the best fit for their organisation

Data Science Platform Consulting & Design

Swiss Watchmaker

Provided consulting services for new data science infrastructure and platform selection to allow for more advanced projects in the future

Problem

- Limited storage and computing infrastructure for data science

- Tedious and manual start-up of data science projects

- Lack of governance for AI projects

Solution

- Consulting advice for new data science infrastructure and platform

- Conducted status-quo analysis of the current platform landscape and developed target architectures for both on-premise and PaaS alternatives

Impact

- Helped in gaining a better understanding of future platform alternatives

- Provided insight on how to create a secure and shared environment to host production-ready data science projects

- Established a clear target infrastructure

AI Sales Forecasting

Major Swiss Chemical company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Problem

- The customer was looking to automate the sales forecasting process which to date was performed in a manual way, making it cumbersome and error prone

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

AI Automated Forecasting

Swiss Chemical Company

Developing a state-of-the-art forecasting approach by combining multiple forecasting models to achieve a 97-98% accuracy, leading to monetary and time savings

Challenge

- Needed to accurately forecast sales, raw materials supply and market demand for finished goods

- Existing forecasting methods were labour-intensive and inconsistent

- Models failing to provide accurate, reliable forecasts

Solution

- Created powerful new methods to generate and combine forecasting models

- Developed modern, state-of-the-art forecasting algorithm

- Delivered an automated solution which aggregated data sources and combined forecasting models together to attain higher accuracy

Business Impact

- Reached 97-98% in forecasting accuracy through combination of forecasting model, higher than any single model on its own

- Enabled an optimisation of operations, resulting in monetary and time savings

- Decreased risk of manual errors through forecasting automation

Logistic Base Optimisation

Swiss Chemical Company

Creating custom statistical algorithm to define optimal “logistic bases” for formulas in order to minimize the amount of pouring and reduce costs

Challenge

- Ingredients need to be mixed at certain ratios to create flavours. Some ingredients are pre-mixed into what is called “logistic bases” to reduce the number of pours

- Choice of logistic bases by human expert is becoming harder

- Goal to find optimal logistic bases through an algorithm to increase pouring efficiency

Solution

- Created custom statistical algorithm that incorporates information about the creation process and historical production data

- Solution was however not implemented because deemed too risk to change the whole production process

Business impact

- Theoretically, the new logistic bases created through our algorithm would reduce the number of pours by 10%

- Would lead to a cost reduction after break-even with initial production process change investment

Production Line Optimisation

Swiss Chemical Company

Analysing a production line to improve production speed and anticipate slow-downs resulting in 15% speed-up with a 8x ROI

Challenge

- Perfume production plant efficiency was very variable and production encountered several slow-downs

Solution

- Conducted initial data analysis and discovered that slow-downs were caused by some valves being clogged

- Cleaning the valves lead to overall equipment effectiveness (OEE) improvements

- Built custom application to monitor KPIs in real time and alert operators about undetected issues

Business impact

- Increased production line efficiency and speed

- OEE increased by 8%, speed-up of production by 15%

- 8x return on investment

Process Order Optimisation in Manufacturing Line

Swiss Chemical Company

Defining an mathematically optimal manufacturing sequence order to reduce total production time of perfumes

Challenge

- Manufacturing line produces perfumes by blending ingredients

- Sequence order can be optimised to reduce time and complexity of production

- Goal to compute optimal scheduling to pour ingredients for each blend

- Past factory data was scarce and implementation initially seemed complicated

Solution

- Implemented mathematical optimisation algorithm that defined optimal production sequence to manufacture perfumes

- Simulation to test impact of different optimisation methods compared to what happens in the factory

- Chose “Iterated Greedy” method

Business impact

- Faster manufacturing due to mathematically optimal production sequence

- Approx. 3% improvement in manufacturing speed

- Resulting in 6 digits cost saving figures

Data Platform Selection Advisory

German Automotive Company

Delivering a comprehensive report comparing 7 data platform solutions and advision on best option to steer future data platform strategy

Challenge

- Wanted to implement new data & analytics solution for core use cases

- Needed to review available data platforms before deciding on a strategy, preferably selecting a low-code option

Solution

- Combined research efforts with our expertise to advise on the best data platform which would fit the client’s needs

- Compared and ranked across 7 dimensions (e.g., ease of use, data governance, etc.)

- Delivered comprehensive final report with best option recommendation

Business impact

- Client able to steer data platform strategy thanks to full report comparing 7 solutions across 7 dimensions

- Ensured that no data platform provider would be overlooked prior to decision making

Residual Value Forecasting

German Automotive Company

Developing and deploying a predictive model for residual value forecasting of vehicle portfolio, resulting in more accurate forecasts and higher margins

Challenge

- Large portfolio of vehicles across the globe

- Need to accurately determine accurate monthly payments and residual value on leasing contracts

- Central computation of residual value difficult as criteria vary from one country to another

Solution

- Worked together with internal team to integrate multiple data sources from the past 12 years together

- Deployed linear regression model refined by incorporating our forecasting expertise

- Applied state of the art model improvements to gain in transparency and control over the learning and predictions

Business impact

- More accurate prediction in residual value compared to existing model

- Increased transparency and explainability of results

- Enables future improvements as model was designed with scalability in mind, ensuring that results stay accurate as new data becomes available

Immuta Evaluation

German Automotive Company

Developed and conducted benchmark to analyse fit for purpose level of SaaS solution on data access and governance

Challenge

- Client interested in deploying IMMUTA SaaS solution to handle data access and governance

- Needed advice and technical due diligence before committing significant resources to integrate the new platform

Solution

- Conducted a benchmarking of the SaaS solution using requirements defined by client and presented results in a workshop

- Benchmarking conducted considering different end user perspectives, including topical deep dives and live demos

- Developed possible deployment scenarios

Business impact

- Received expert assurance that IMMUTA solution was fit for purpose and worth the investment

- Able to anticipate potential future weaknesses of solution and develop workarounds in advance

Design and Implementation of D&A Solution on Azure

German Automotive Company

Created infrastructure to enable quick Dataiku setup on Azure, with custom plugins and altering system resulting in higher scalability and fewer downtimes

Challenge

- Maintenance of existing Dataiku platform was too time consuming and the platform was failing too frequently

- Many steps needed to be done manually, both from user and administrator side

Solution

- Created an infrastructure as code scripts to enable a quick Dataiku setup on Azure

- Developed custom Dataiku plugins to enable more self-service for governance

- Integrated with additional (Azure Data Lake and Kubernetes)

- Created monitoring system to gain real time insights on system performance

Business impact

- Enabled much higher self-service capability on platform, simplifying usage and administration

- Scalability both in terms of storage and compute

- Fewer and shorter downtimes on platform

- Monitoring system integrated with Teams enables quick reaction to emergencies

MLOps & Data Governance

German Automotive Company

Defining model guidelines and developing data governance for data lake resulting in successful deployment of models compliant with strict regulations

Challenge

- Client in middle of a digital transformation and experimenting with big number of ML use-cases on proprietary data platform

- Need to operationalise some ML models while avoiding lock-in of vendor platform

Solution

- Implemented guidelines for model training, deployment and maintenance in hybrid environment

- Developed data governance for data lake

- Built model-serving layer bridging the gap between Dataiku and Kubernete

Business impact

- Successful transition from experimentation phase to deployment of multiple ML models while maintaining strict standards of Finance Department

- Client was able to integrate model with multiple client-facing applications

Open Source D&A Platform

German Automotive Company

Supporting the creation of an entirely open source Data & Analytics platform, enabling a self-service and hassle-free approach to development

Challenge

- Product silos prevent efficient collaboration across different teams

- Processes often done manually and require multiple approvals, slowing down development

- Client tech department lacks public exposure, preventing them from hiring top talents

Solution

- Currently supporting the development of an entirely open source Data & Analytics platform

- Exploring existing open sources solutions, making them enterprise ready, adding functionalities based on client needs, and integrating them into existing services

Business impact

- Increased exposure to the open source world and to other companies interested in the topic

- Self-service approach for users to develop solutions with minimal friction

- Enabled internal teams to discover state-of-the art data solutions that Unit8 used

Architecture and Implementation of D&A Platform

German Automotive Company

Helped in designing and testing future D&A platform in collaboration with internal team resulting in clear architecture and migration scenario

Challenge

- Goal to prepare conceptual blueprint for new D&A platform avoiding known pitfalls from previous one

- Faced paradigm shift because data lake originally planned was replaced by data mesh

- Need to develop many architectural concepts from scratch due to data mesh concept being scarcely used in productive use cases

Solution

- Together with internal team, prepared documentation of technical concepts and requirements, and created several PoC in various areas

- Defined platform operation and testing concept

- Carified architecture to make it compliant to internal policies

- Helped prepare for migration

Business impact

- Clear platform architecture enabling stable deployment components compliant with design and requirements

- Pre-defined migration scenario easy to execute in production environment

- Internal team can now operate more autonomously

Azure Event Stream Architecture

Swiss Mountain Rescue Company

Providing best practices to the client’s technical provider through a workshop and delivering an optimal architecture design to implement new solution

Challenge

- Wanted to introduce more scalable Azure-based streaming platform to collect location data from rescue helicopters more frequently

- New device to be installed would send location data 15x more frequently which would overload current infrastructure

Solution

- On-site meeting with technical provider chosen by client to conduct a workshop and provide best practices on streaming architecture

- Delivered optimal streaming architecture design after careful comparison between different alternatives

Business impact

- Consulting project without implementation from Unit8

- Helped client’s technical providerto define best approach for new architecture

- Could enable new use cases thanks to higher frequency location data availability

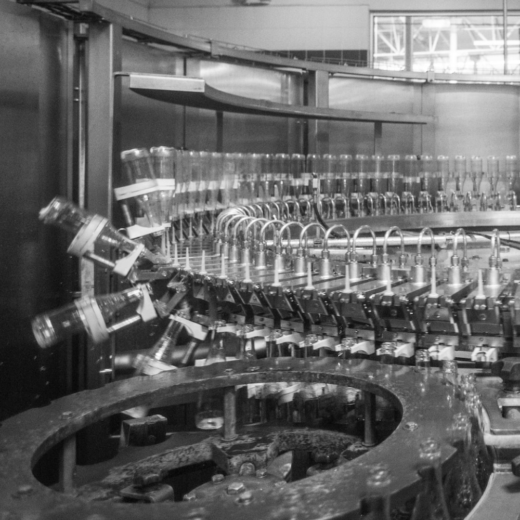

Digital Twin & Production Line Simulation

Glass Bottle Manufacturer

Developing tools on Foundry and applying causal models to identify optimal steps in glass bottle production process to increase yield of production line

Challenge

- Want to improve yield on production line form 86% to 90%

- Already identified step in process where gain could be realised

- But no way to automatically prioritise sensor data which should be further analysed

- Goal is to apply ML models to identify most promising captors to improve yield

Solution

- Initially built E2E model of yield on production line, but hit data quality roadblock

- Shifted towards:

- developing tool on Foundry to surface “golden production parameters” when production quality was high

- using causal models to understand optimal actions to stabilise first step of production process

Business impact

- Highlighted data quality issues and suggested next best steps for improvements

- Demonstrate Foundry’s ability to replace existing system

- Trained key internal stakeholders on Foundry platform

- Due to lack of high quality sensor data → no direct impact on yield realised during the PoC

AI Supply Chain Forecasting

Major Swiss Chemical company

Problem

- The need to improve the current forecasting process (raw-materials, finished goods and sales)

Solution

- New approach to improve forecasting quality and the effort needed to maintain it using new data sources like Forward looking indicators, Financial metrics: (GDP, Inflation, FX rates) and Big events (e.g. new years in china, olympic games etc.)

Impact

- Automation -> less manual work, less errors, less time

- Higher accuracy (97-98%)

- Better planning/cost savings

Aircrafts Predictive Maintenance

Airplane producer

Implementing a data platform to centralise maintenance data from hundreds of airlines and enable predictive maintenance models

Challenge

- Integrate data from 100s of airlines on a single platform

- Reduce or eliminate operational interruptions and minimise the number of aircrafts immobilised due to unforeseen maintenance needs

Solution

- Integrated sensor data and telemetry into central data lake

- Developed predictive maintenance model outputting the probability of maintenance need in the next 5 flights for each aircraft

Impact

- Notable improvement in speed of problem detection, triaging and resolution

- Enabled feedback loop to aircraft design teams to prevent similar issues from reoccurring

Forecasting platform

Major German Automotive

Problem

- Our client, a global automotive company, lacked a central data platform for forecast generation and analysis. As a result, its teams could not collaborate or analyze data efficiently.

Solution

- a modern data platform with long-term scalability was scoped, designed and implemented together with the initial first Proof of Concepts

Impact

The new platform enables the customer to:

- Develop and operate forecasting models quickly and consistently

- Collaborate on and reuse models, preventing redundant code development

Data lake buildup

Major German Automotive

Problem

- Siloed data spread across multiple systems

- Inability to properly analyse manufacturing/test/sales data on a common platform

Solution

- New data infrastructure architecture and buildup

Impact

- Enterprise data lake. Governed, and secured

- Foundation for the analytical use cases

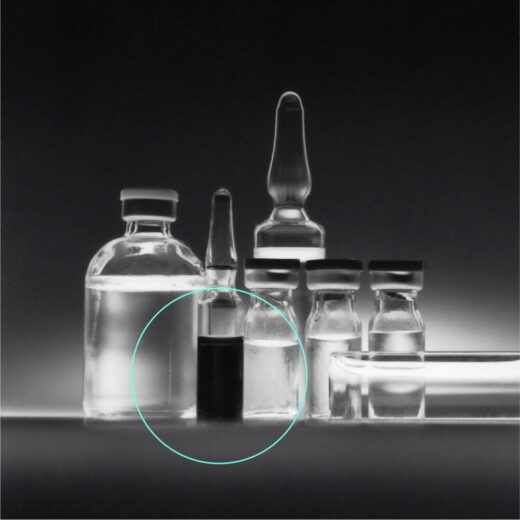

Production line continuous monitoring

Swiss division of a Global Pharma

Problem

- The customer’s production line went through a data driven optimization, the customer wants to ensure the production line maintains the highest possible OEE and wants to add advanced features like automated issue detection & prediction

Solution

- Near real time continuous monitoring system of key production processes with advanced analytics built in (alerting, trend detection, anomaly detection, predictive maintenance)

Impact

- Greater production process visibility

- Quicker time to resolution

- Improved uptime

Production line optimization

Swiss division of Global Pharma

Problem

- Running out of production capacity, significant CapEx investment needed in the new production line to keep up with demand

- Goal: increase the production capacity by 5% via advanced analytics

Solution

- Data integration, AWS platform

- Anomaly detection algorithms

- Data correlations -> insights -> recommendations

Impact

- Trending towards 11% of productivity increase (throughput and yield optimization)

- 15x ROI

Residual value prediction

German automotive

Problem

- Car manufacturer holds large global leasing portfolio that has to be periodically evaluated

- Current valuation predictions are inaccurate

Solution

- Based on a large volume of past transactions (12 years) and cars parameters (model, mileage, options), etc. predict accurately the residual value of the car

Impact

- Accuracy of the valuation improved by $100M’s (from large overall base value)