How can we help? Please reach out to learn more

Workshop – Data-driven Strategy

Multinational Life Sciences Company

Data Science Platform Consulting & Design

Swiss Watchmaker

AI Sales Forecasting

Major Swiss Chemical company

AI Automated Forecasting

Swiss Chemical Company

Logistic Base Optimisation

Swiss Chemical Company

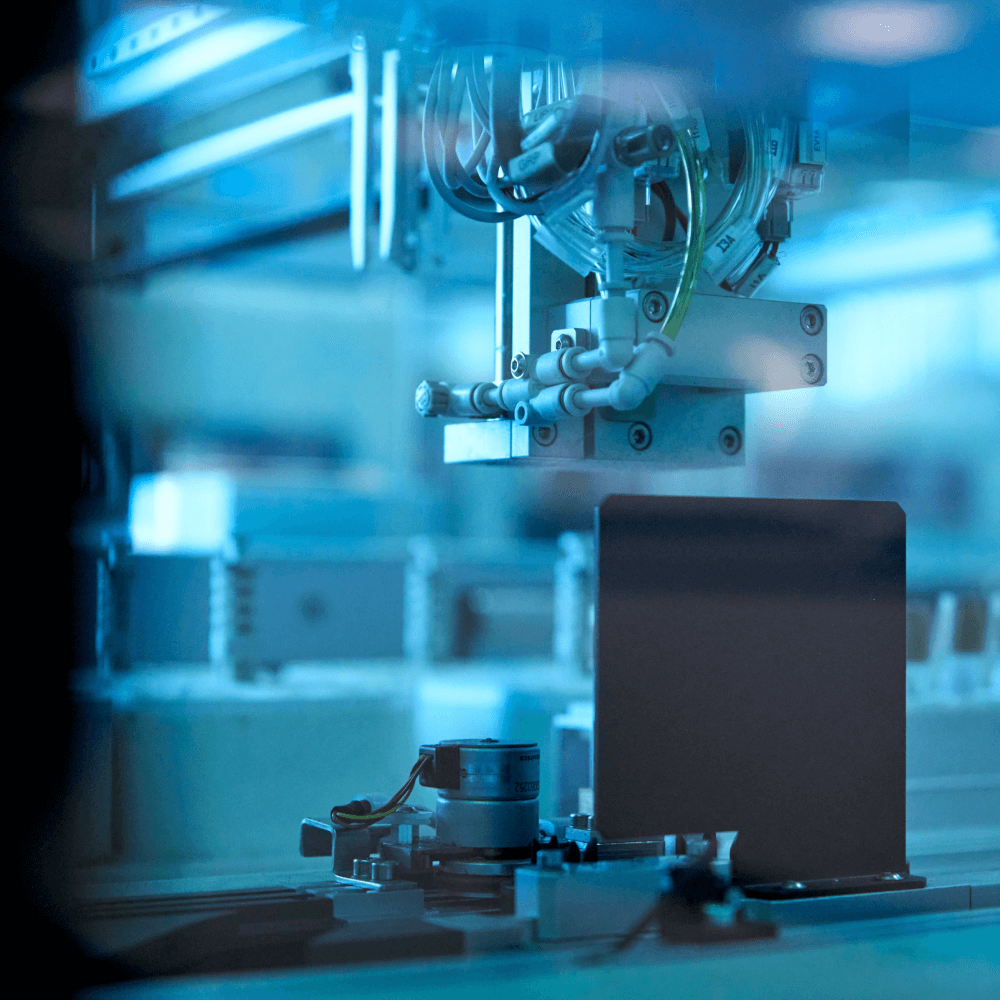

Production Line Optimisation

Swiss Chemical Company

Process Order Optimisation in Manufacturing Line

Swiss Chemical Company

AI Supply Chain Forecasting

Major Swiss Chemical company

Production line continuous monitoring

Swiss division of a Global Pharma

Production Line Optimisation

Swiss Chemical Company