2.1

R&D

Product development (e.g. chemical reaction prediction, compound classification)

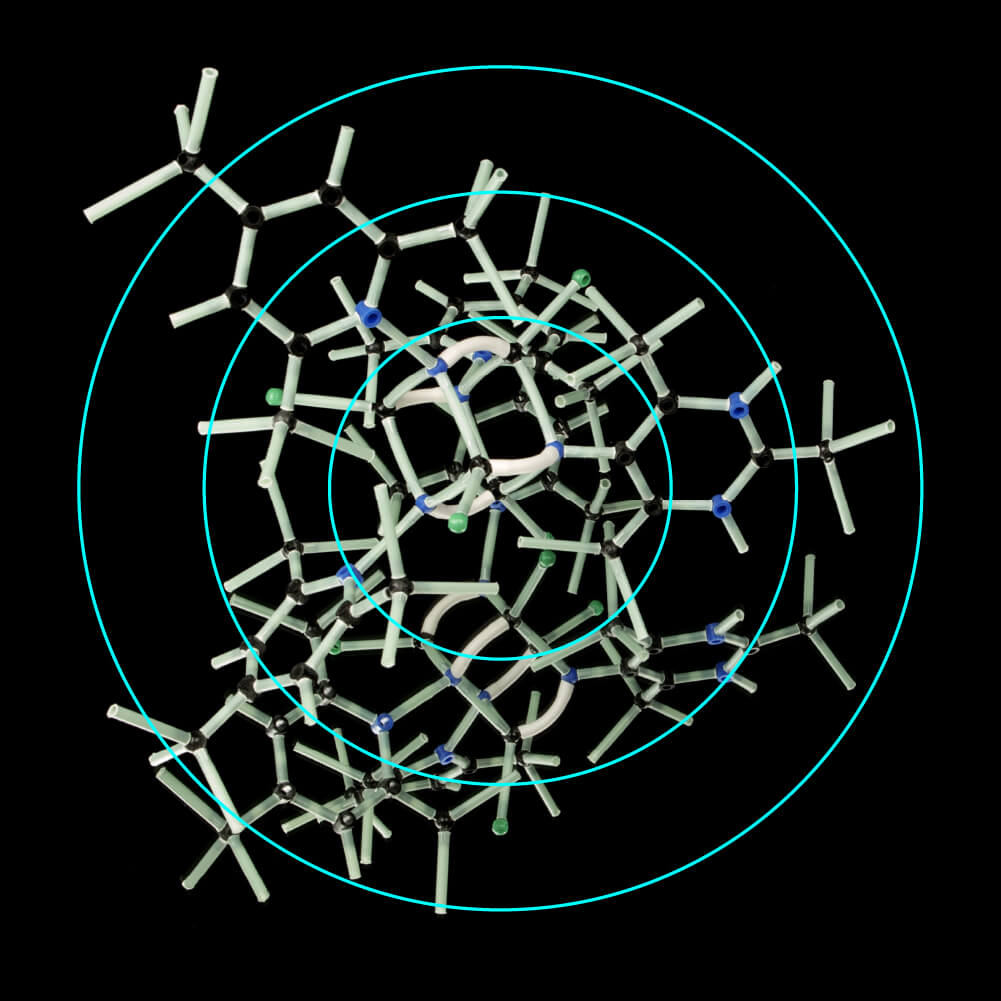

Several regression and classification techniques can accurately predict the properties of hypothetical molecules that would allow researchers to synthesize only the most promising ones. Next, similar models can be used to predict a given reaction outcome, as well as the necessary conditions for that reaction to happen.

Product design (e.g. molecule design)

Designing new molecules requires deep domain knowledge and creativity. However, inherent limitations to the human mind are overcome by emerging deep learning algorithms. They support researchers in many ways, as they can generate huge numbers of molecules in rather short times, and are less biased than human creativity if well built.

Product optimisation (e.g. change formula to improve attributes and/ or reduce cost)

The search for optimal reaction conditions requires many synthesis trials and errors, in particular when there is a significant number of adjustable parameters to control. Recurrent neural networks facilitate this lengthy process by iterating over all the possible parameter combinations to quickly find an optimal solution, depending on your target.

Virtual testing and prototyping

Computer programs specialized in retrosynthesis are commonly producing outputs of a lesser quality than the ones done by expert chemists. Yet, high-performance ML-based algorithms show strong potential to assist organic chemists in the early stages of retrosynthesis.

2.2

Production

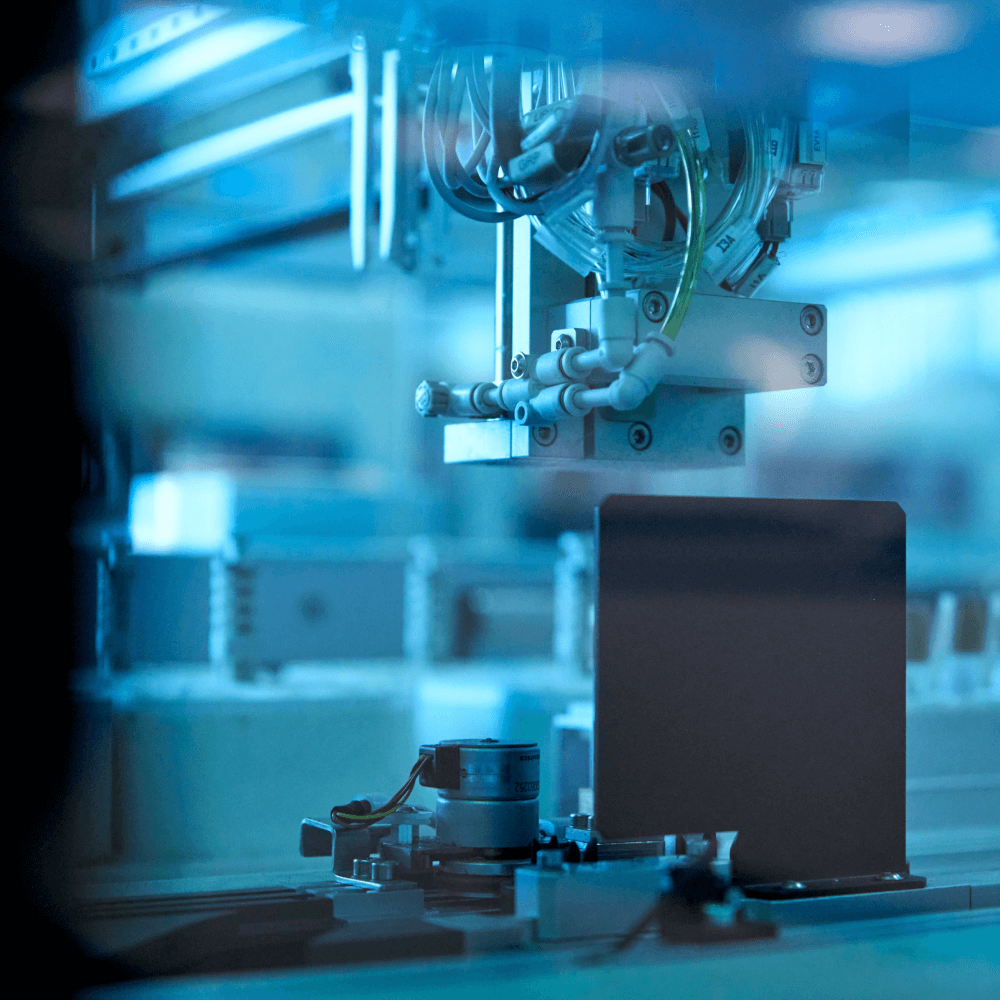

Predictive maintenance

Advanced machine learning models can recommend optimal times to conduct maintenance by analyzing root causes and identifying drivers of machine downtime. Implementing these recommendations will help prevent future asset failures and unplanned downtimes, hence minimizing production losses while maximizing OEE (overall equipment effectiveness).

Production capacity optimization

Optimizing production capacity is a never-ending process in an asset intense business area like the chemical industry. With the help of predictive analytics and sensor technology, you can for instance reduce unplanned downtime, improve work planning and scheduling or reduce spare part inventory. This results in higher asset availability, maximized hands-on-tool time, and improved spare part availability.

Production simulation and optimization (e.g. via virtual plants/ digital twins)

Increasing plant complexity implies sophisticated ways of approaching KPIs and targets as multi-dimensional factors complexify the decision-making process. As a decision support tool, a digital twin can reduce this complexity as it works in the present by simulating the actual device, but with thorough knowledge of its historical performance and an accurate understanding of its future behavior.

Inventory management (incl. forecasting)

Planning demand ahead of time and in an accurate manner is key to any optimized inventory management system. With insights gathered from predictive analytics and advanced forecasting, AI-based models anticipate changes in demand, resulting in a more accurate production schedule, a reduced number of off-spec chemicals, and fewer slowdowns and downtime.

2.3

Sales & Distribution

Sales forecasting

Sales, marketing and planning teams of chemical suppliers can use AI to automate and improve the quality of their sales forecasting processes. For instance, building a predictive pricing model based on forward-looking indicators, financial metrics and big events can be a quick win for any organization. It has the potential to increase the transparency of business-critical decisions and overall transform the demand forecasting and supply planning process.

Sales Force steering (e.g. lead scoring, improve cross-selling/ up-selling)

AI-based sales tools and processes have the potential to improve win rates on deals in your aftermarkets via automation of lead qualifications, cross-selling and upselling. Current tools can qualify existing customers as leads in seconds, and as a result save inside sales a tremendous amount of time while moving closer to making an aftermarket sale.

Marketing budget allocation

Machine learning often outperforms humans when it comes to drawing trend conclusions. Being aware of the market’s receptivity makes it possible to adapt the communication and marketing budget according to market trends.

2.4

Environment & Safety

Environmental management (e.g. reduce emissions through smart steering of plant)

Monitoring your energy consumption through machine learning-based models can result in a tremendous reduction of emissions. Smartly steering your plant will allow you to move towards an improved energy sourcing mix depending on your needs (e.g. spot market vs contract).

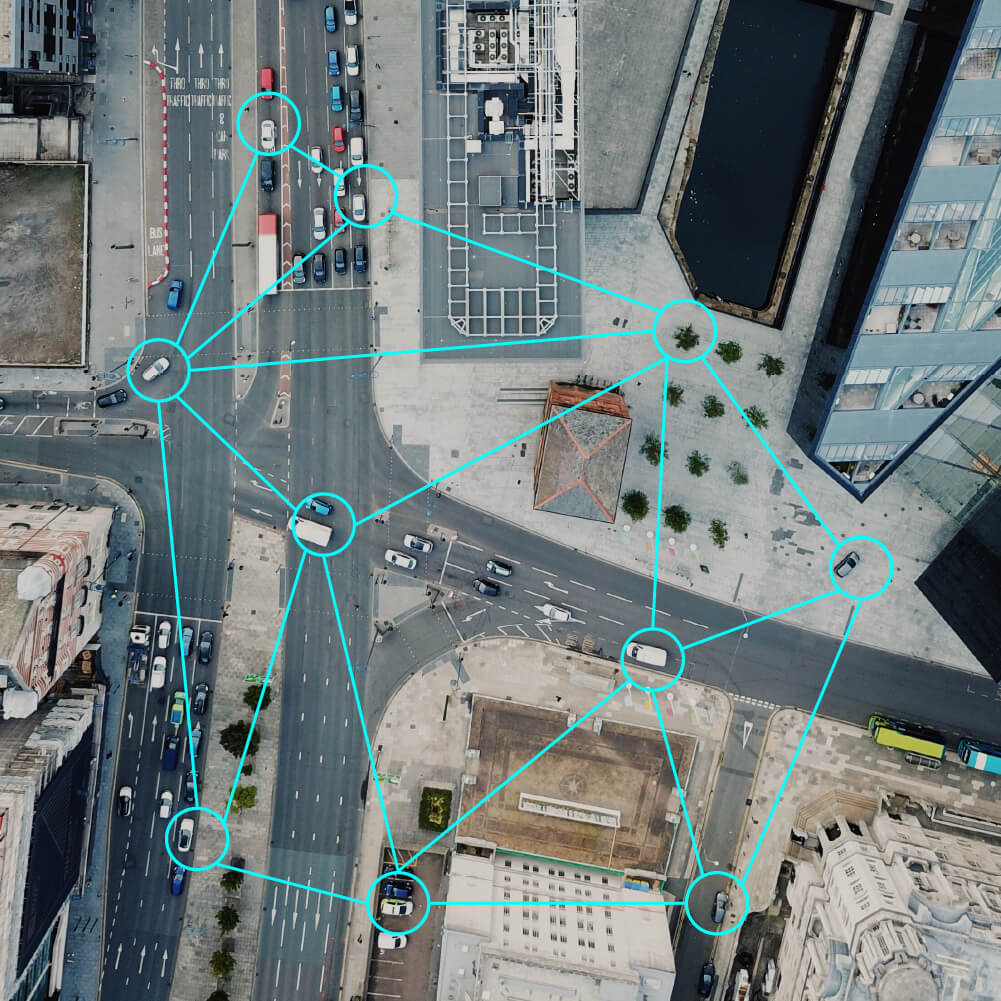

Safety management (e.g. remote monitoring to improve worker safety)

Your plant operations can be monitored on a near-real-time basis with AI-driven solutions, allowing you to assess accordingly the risk associated with each activity. Workers can then focus on the safest tasks, while high-risk activities can be delegated to robots, improving the overall safety of employees. Moreover, AR and VR devices can now be used to train employees in a risk-free environment, minimizing the risks of injuries.