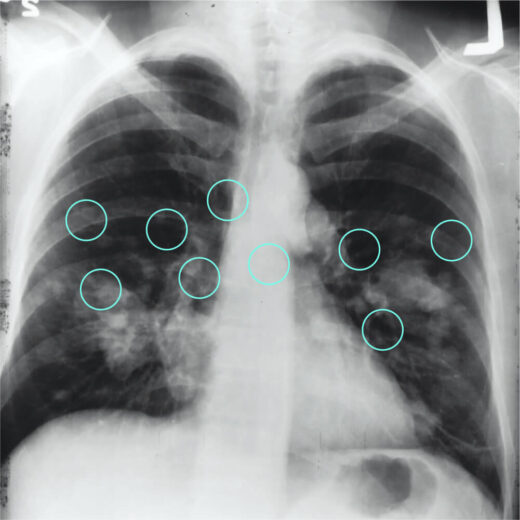

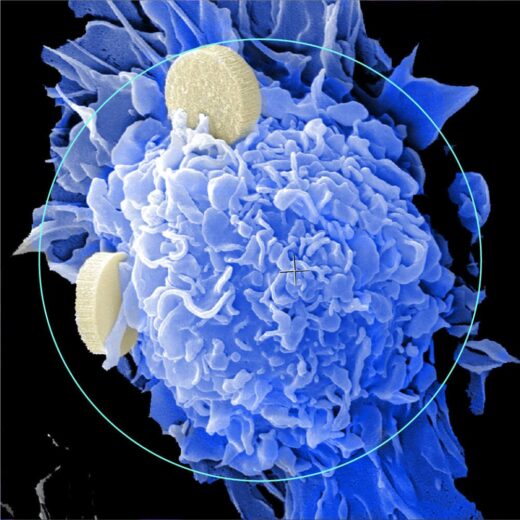

Detecting pneumonia in x-ray images

Pro bono

Problem

- Pneumonia causes over 1M deaths a year

- Cost effective process needed for diagnosing X-Ray scan images

Solution

- Pro-bono research work to develop a predictive model for the diagnosis

Impact

- 92% of accuracy

- Model published -> available for researchers

Sustainability Module

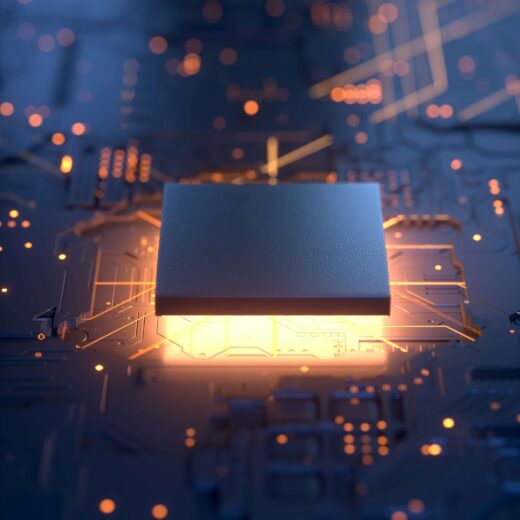

Multinational Pharmaceutical Company

To address the challenge of inadequate sustainability data sharing in the semiconductor industry, which leads to inaccurate carbon footprint calculations

Challenge

- Insufficient sharing of sustainability data among companies in the semiconductor industry

- Inaccurate carbon footprint calculations due to lack of access to comprehensive data

Solution

- Development of a sustainability module within customer’s data-platform specifically for the semiconductor industry

- The module enables companies to calculate the carbon footprints of their products accurately

Business Impact

- It facilitates the request and sharing of footprint data between suppliers and customers

- Potential for significant improvement in the accuracy of carbon footprint calculations across the industry once the platform is fully operational

- Expected enhancement of industry-wide sustainability efforts through better data transparency and collaboration

Data Science Module

Multinational Pharmaceutical Company

Developing a data platform to enable the semiconductor industry to manage and analyze vast production data, aiming to significantly improve product quality and process optimization

Challenge

- The semiconductor industry is flooded with a large volume of production data, including test results from every stage, from raw materials to the final product

- The industry faces the challenge of effectively organizing and interpreting this data to enhance product quality and streamline manufacturing operations

- Lack of expertise in data science methodologies to maximize the value derived from this extensive data

Solution

- Unit8 is helping customer in creating a data-platform tailored to the needs of the semiconductor industry

- We assisted a potential customer’s end users by processing their data and applying data science techniques

- Our analysis identified which ingredient tests are most critical for the quality of the final semiconductor product

Business Impact

- While the impact of the solution is not currently quantifiable due to the Platform being in its development and scale-up stages, the potential outcome is expected to be a transformative enhancement in data utilization within the semiconductor industry

- Platform is designated to provide advanced analytical tools and methodologies that transform raw data into valuable insights, leveraging its data for quality control and process optimization

Platform development – Foundry

Multinational Pharmaceutical Company

Developing the modules and core administrative part on a Foundry-based data platform

Challenge

- Managing the development of the core administrative components of the platform requires a deep understanding of the platform’s architecture and requirements

- Ensuring that the platform is scalable and can handle large amounts of data can be a challenge

- Planning & Maintaining the security and privacy of the data on the platform

Solution

- Development of customer’s Fundry based data platform

- Developing various features and data pipelines for the platform, including data processing pipelines, metrics computations, and dashboard design and implementation

- Development of several modules, including the Sustainability, Audit, Data Science Module, Use Case Portal

Business Impact

- The platform is scalable and can handle large amounts of data while maintaining the security and privacy of the data

- Platform will become accessible to many users in the future

- Appraisal from CEO & continuation of the project

Medical Copilot

Swiss Telemedicine Provider

Enhance patient care quality and improve patient satisfaction by recognizing medically-important information.

Challenge

- Physicians spend a lot of time documenting the medical consultation content and spend more time on administrative tasks than consulting patients

- Data was lacking quality since everything related to medical consultations was coming via manual input and thus no standards for data quality were followed

- Patient satisfaction was dropping (lower NPS)

Solution

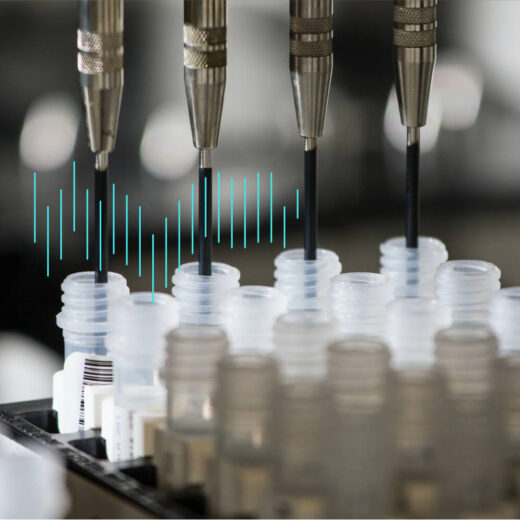

- Speech-to-Text solution in German has been developed

- Appropriate information is automatically detected and populated in the right fields using AI components (e.g. medical entity recognition)

- Provided a medical consultation summarizer API using Azure OpenAI services that condenses the content of the medical interview, while maintaining key information.

Business Impact

- Physicians focus on consulting patients than performing administrative tasks

- Data quality improved significantly since data comes standardised out of AI components

- Patient satisfaction increases since they feel that they are heard more and treated better

Intelligent Document Insight Assistant

Multinational Cosmetics and Pharmaceuticals Company

Implementing a secure Assistant helps with information retrieval, enhances collaboration & ensures compliance

Challenge

- Document fragmentation: The company struggles with scattered documents across various platforms like SharePoint, in different file formats (Excel, PPTX, PDF)

- Non-Searchable Old PDFs: The company faces the issue of old PDF documents that lack searchability; valuable insights and data may remain hidden

- Adoption of GenAI capabilities by end users

Solution

- Unit8 GenAI Accelerator has been used to buid custom SafeChat, Q&A and FileChat use cases has been deployed

- Implement custom file parsers, specifically for pptx and aspx files, to enable document processing and extraction of relevant information

- Ensure the deployment of the solution is done in a production environment with no internet exposure

- Utilize an application gateway to provide secure access to the chatbot, protecting it from unauthorized access and potential security threat

Business Impact

- Users can save time and effort by quickly finding specific information within documents through the chatbot’s search capabilities

- Simplified Document Management: Centralized access eliminates the need to navigate through multiple locations

- Users can upload their own files, providing tailored document access and search capabilities

- Safe content generation and interaction capabilities facilitate collaboration among employees, enabling them to share insights & exchange idea

Employee Support with Secure GenAI Chat

Swiss Biotechnology Company

The company sought to implement secure GenAI solutions, beginning with an HR-focused Retrieval-Augmented Generation (RAG) system

Challenge

- A non-tech company with small AI experience sought to initiate digital transformation

- The lack of an internal AI-powered chatbot led employees to use public platforms like OpenAI’s ChatGPT, raising data protection concerns

- The company aimed to implement secure GenAI solutions, starting with an HR-focused Retrieval-Augmented Generation (RAG) system, but lacked the necessary infrastructure and expertise

Solution

- A secure, internal Chat GPT-like application, with HR assistant with access to policy documents; made possible by our GenAI Accelerator

- Improved multilingual search and document retrieval capabilities

- Personalized prompt libraries for individual employees

- Customized front-end aligned with the client’s branding

- Robust DevOps and deployment pipelines

Business Impact

- Global ChatGPT-like tool for all employees, improving productivity and innovation

- Improved HR query resolution through the AI-powered assistant

- Enhanced data security by providing a controlled, internal AI environment

- A scalable AI infrastructure, facilitating easy addition of future use cases

- Business user’s satisfaction and efficiency through personalized AI interactions

From Tribal Knowledge to Digital Intelligence

A hybrid platform that intelligently captures, curates, and distributes engineering knowledge through automated workflows and human-guided validation.

Challenge

- Knowledge capture is complex and time-consuming as senior engineers lack structured methods to document their years of expertise and tacit knowledge effectively

- Ensuring that only relevant and updated information is processed and retrieved

- Finding a hybrid solution balancing AI and human review

Solution

- The solution has been built using Unit8 HyperScaler

- Integration with ticketing platform that automatically converts resolved support tickets into AI-searchable knowledge articles, enabling support agents to access historical solutions through conversational interface

- Creating an improved SharePoint Connector capable of processing only the files that need to be updated

- Sorting the database of customers products and retrieving information only for the relevant ones selected by the user

- Role-based access control with multiple specialized Q&A chatbots for different use cases

Business Impact

- Instant access to a comprehensive, up-to-date knowledge base of service manuals and internal articles

- Service plus, chatbot helping field engineers and capturing “tribal knowledge”

- Reducing the chance of hallucinations

- Increased self-sufficiency and knowledge democratization: Team can independently create RAG use cases without constant external support

- generation of contextual “nuggets of knowledge” from support ticket data using specialized AI summarization

- Significant reduction in data processing costs by ensuring only changed files are copied

Regulatory Reporting & Pharmaceutical Documentation Workflows

Multinational Pharmaceutical Company

Data automation solution reduced regulatory documentation workload and delivering annual savings through strategic process redesign

Challenge

- Multiple Production Facilities: Data is distributed across different systems in various manufacturing locations, creating complexity in data consolidation

- Regulatory teams currently spend extensive time manually gathering, cleaning, and transforming data from disparate sources

- Numerous documents require detailed quality data in tabulated formats, demanding repetitive administrative work

- Each finished good requires a separate data compilation and documentation process, slowing down regulatory submissions

Solution

- Developed a Proof of Concept (POC) to collect data from multiple LIMSs into an AWS staging zone

- Data ingestion into Foundry, followed by transformation, user validation, and automated document generation

- Intermediate ontology that would store this data for future use and for sharing with the other departments that would need access

Business Impact

- The total impact of the production solution that would come after the POC was calculated in a few millions per year by reducing the time spent on the manual data preparation and validation task

- Automated generation of necessary reports

- Potential for resource reallocation to more strategic tasks due to time saving

Carbon Clarity, AI tool for Carbon Footprint Assessment

Multinational Pharmaceutical Company

How has the new Unit8 solution improved customer’s carbon footprint evaluation process?

Challenge

- Customer’s departments are required to verify the carbon footprint values provided by its suppliers. This process is not only labor-intensive but also prone to errors, which can compromise the integrity of our assessments.

- There is a challenge in identifying which carbon footprint values need correction. In many instances, there were products for which no valid carbon footprint data were available (even thousands of such cases to address)

- Although company has a team of skilled life cycle assessment experts, their capacity is limited. With thousands of cases to address, customer’s current manual processes are not sustainable

Solution

- An AI-powered tool has been designed to evaluate the quality of Product Carbon Footprint (PCF) values and identify suitable proxies for Life Cycle Assessment (LCA) calculations.

- User Input Analysis: Users provide details such as material name, geography, and production processes. The newly created tool then searches a database for similar entries.ensuring accurate and relevant results

- Using OpenAI model embeddings, the tool identifies similar materials with cosine similarity. For brief inputs, it generates additional information to enhance search accuracy

- The solution verifies user-provided carbon footprint values; if no PCF is provided, it suggests similar materials

- For large-scale needs, users can submit bulk requests via Excel, with results available the next day.

Business Impact

- Tool implementation significantly speeds up the evaluation of carbon footprints, enabling experts to quickly prioritize and review materials that are most out of range.

- During development, we assessed approximately 5,000 different materials to ensure that Carbon Clarity provides comprehensive coverage and accuracy. This extensive database supports a wide range of materials and scenarios.

- The Unit8 solution offers a novel and in-depth perspective on the PCF database, facilitating more thorough and insightful analysis.

Achieving Business Value Creation through GenAI Infra and Use Cases

MedTech Company

Accelerated integration of the Unit8 Hyperscaler on top of the existing Azure architecture, with implementation of 11 high-value MVP use cases

Challenge

- Immature D&A landscape, not allowing for advanced analytics implementations

- No real business empowerment of business functions through advanced D&A solutions

- Extensive manual labor required across key business processes supporting core business functions (e.g. quality, aftersales, marketing, procurement)

Solution

- Integration of Unit8’s GenAI hyperscaler in a matter of weeks

- Carried out GenAI use case ideation and roadmapping exercise across all business functions, prioritizing high-added value ideas

- Implementation of 11 GenAI MVPs leveraging RAG methodology, in 9 months

Business Impact

- Significant cost saving opportunities enabled by the adoption of GenAI use cases (e.g. automated similarity detection between quality incidents, repair manuals Q&A)

- Show-cased the value of GenAI solutions at scale, paving the way for a multi-year GenAI roadmap

Foundry Acceleration

Healthcare company

Established Foundry dashboard to track financial and operational KPIs, enabling a measured approach to ensure delivery of client value

Challenge

- Provide online and personalized mental health care for families & children with a focus on prevention, early identification and treatment of diseases

- Accelerating startup development, the challenge lies in effectively leveraging Palantir Foundry to monitor internal KPIs and deliver the committed digital experience to care providers and parents.

Solution

- A thorough initiation encompassing project setup and robust data governance

- Established an initial data model and ontology, along with a workshop-derived dashboard for tracking financial and operational KPIs

Business Impact

- Swift establishment of their end-to-end data pipeline.

- Advancement in their application development maturity

- Improved business objectives, identified and addressed operational issues, earning direct praise from the CFO

AIP-Generated Insights for driving HR efficiency

Multinational Pharmaceutical Company

Using AIP for a Foundry-based chatbot prototype that automates HR data insights

Challenge

- The current process of manually setting filters in dashboard for visualizing HR Data is time-consuming

- The dashboard lacks the ability to generate deeper, LLM-driven insights beyond basic data visualization

- Difficult navigation and limited insights make it challenging for HR professionals to quickly identify trends, understand root causes

Solution

- Foundry-Based Chatbot Prototype has been developed to address the HR KPI access challenges

- Instead of mouse-clicks, users can simply type a question. Follow-up questions are possible and chat sessions are saved automatically

- A relevant chart is generated automatically, but can also be customized. Simple text insights and calculations can be generated. Misspelled words or department names are understood.

Business Impact

- Speeds up the process of finding data: HR professionals previously spent time on manual data retrieval and filter application, freeing up resources for higher-value activities

- Clear, text-based insights to help HR users quickly understand and act on the data

- Now customer team in evaluating our Foundry solution against alternatives, ensuring a well-informed decision.

R&D Acceleration: AI-Powered Reporting & Manufacturing Scalability

MedTech Company

An AI-powered report generation platform was implemented to automate R&D documentation for FDA submissions, accelerating product development and establishing a data foundation

Challenge

- The R&D department needs to generate experimental reports to document their product’s effectiveness and safety, including FDA submissions

- With mass production on the horizon, the company lacked a robust data platform to accelerate development cycles and optimize future factory operations.

Solution

- Our proprietary solution with pre-built use cases was deployed to establish a foundational data platform

- LLM-powered report generator automates content creation by taking a protocol document and observational data as input

- The solution includes an interactive editor, allowing users to refine the generated text and chat with the AI model for precise adjustments, ensuring accuracy and compliance

Business Impact

- Core functionalities like SafeChat and FileChat have seen widespread adoption across the company

- Automation of report generation can speeds up the documentation process, enabling faster product development and submission cycles

- Researchers can now focus more on experimentation and analysis rather than on report writing

R&D Knowledge Management Copilot: Realizing $1.5M in R&D Productivity

Global MedTech Manufacturer

Improved information accessibility by implementing an AI-powered conversational interface that retrieves documents from SharePoint repositories

Challenge

- Optical, mechanical, electrical and other R&D engineers use old knowledge bases to consult past product designs (failure events & technical designs) to help them make better design decisions.

- Databases are old systems covering a wide range of topics (from optics to product features to development documentation), where information is hard to find and extract

Solution

- Single application gathering R&D knowledge from 350k documents scattered across Japanese systems

- Provides seamless access via natural language for engineers and researchers to critical product and research documents, accelerating innovation and collaboration

Business Impact

- Estimated productivity gains of 1.5M USD per year from research time saved

- Triggered decommission of old Lotus Notes database, saving the organization 100’000s USD a year in license costs

Accelerated Review of Scientific Publications

Global MedTech Manufacturer

Streamlining of various workflows within Scientific Affairs department, allowing researchers to gain granular insights from newly published scientific literature.

Challenge

- The Scientific Affairs team is in charge of reviewing state-of- the-art literature and passing that knowledge to their R&D counterparts

- The review process consists various manual steps that takes time from extremely specialized and valuable researchers, hence GenAI was used to streamline few identified processes

Solution

- Leverages GenAI to assess, process, and extract data from published scientific literature.

- Chat with publication: direct interactions with uploaded publications

- Template generation: extract relevant information to fill various templates (excel, word, ppt)

Business Impact

- Greatly sped up the literature review process and the creation of summaries, allowing researchers to focus their attention to more productive tasks

- Estimated saving of 1 week of work / month per researcher by reduction of manual foundational work

DWH Platform Selection

Multinational Pharmaceutical Company

Defined requirements and helped selection of the best-fitting DWH platform to integrate the existing technical landscape

Problem

- 5 different business units leveraging a variety of on-prem and cloud data sources to drive business analytics capabilities

- Strong existing architecture landscape in place, based on AWS and Foundry

- Very diverse business needs across sectors, with strong preferences towards specific solutions to be mitigated

Solution

- Strong engagement with stakeholders across all BUs to drive requirements collection

- Assessment of 10+ candidates for DWH implementation

- Orchestrated procurement process with 4 different vendors to determine fit-for-purpose and fit-for-cost viability

Impact

- Selected the optimal DWH candidate to serve the company’s current and future analytics needs

- Ensured buy-in across all Business Units on the way forward to leverage the company’s data

- Enabled 1M$+ saving on selected platform cost vs other candidates

Integrating Cognitive Search & OpenAI

Medical Provider

Challenges Faced by Medical Practitioners in Acquiring Recent Scientific References on Disease Relationships Amidst Time Constraints

Challenge

- Medical practitioners face constraints in time and capacity when searching for relevant content

- Challenges arise when seeking current scientific references to comprehend the correlation between two diseases

- Hallucination risk: Generative models may inaccurately identify or connect irrelevant information

Solution

- Use of Azure-powered tool and combining Cognitive Search & OpenAI

- Implement fine-tuning model or prompt engineering crucial to minimising hallucination risk

- Test: Experiment with limited data source for nephrology articles

- Putting proper guardrails resulted in no response to out-of-context queries, which was the proper and expected behaviour

Business Impact

- Quickly sifts through vast scientific articles

- Doctors can now find references that potentially contradict the mainstream findings to provide the practitioner with a wider view

- Rapid extraction of insights from unstructured data aids informed decision-making

- A competitive advantage achieved in the respective industry

Capacity Planning

Multinational Life Sciences Company

Built a capacity planning tool via Workshop on Foundry, providing visibility on the usage of equipment and enabling the simulation of “what-if” scenarios

Problem

- Capacity planning at a global life sciences company was a manual and tedious process

- The company needed better visibility on the current usage of equipment, and the ability to simulate the impact of changes

Solution

- Workshop application on Foundry

- Metrics monitoring and simulation capabilities via “what-if” scenarios

- Build up of a backend pipeline

Impact

- Reduction of manual work

- Quicker analysis of the impact of simulated changes

- Reduction of human error

Commercial Analytics Workshop

Swiss Pharmaceutical Company

Conducted a one-day workshop for a Swiss pharmaceutical company to advise them on the build-up of a Commercial Analytics CoE.

Problem

- Challenges in scaling analytics from PoC to enterprise level solutions

- Analytics team struggling to find more time for strategic advisory, overloaded with operational activities

Solution

- Knowledge transfer regarding organisational options & best practices for the set-up of an Analytics CoE

- Provided frameworks for the definition of the Analytics CoE’s scope and service levels

- Guidelines and framework for the definition of the Analytics CoE’s operating model

Impact

- Identified the internal clients that the Analytics CoE must serve, along with their needs

- Defined the Analytics CoE’s value proposition and what is needed to enable it

- Drafted the high-level setup of the Analytics CoE

Cross border invoices classification

Multinational Pharmaceutical Company

Developed an NLP pipeline for the automated classification of cross border invoices

Problem

- Wrong classification of cross-border invoices can lead to multi-million penalties risk on a yearly basis

- A global pharmaceutical company wanted to mitigate compliance risk related to the misclassification of cross-border invoices

Solution

- Developed an NLP pipeline, to automate the classification of cross-border invoices through an existing NLP model

- The NLP model reads the invoice and predicts the top classes with a corresponding confidence value

- Highest confidence code is then assigned to ERP field during the transaction posting

Impact

- Time to select coding is significantly reduced

- Increase of compliance and risk reduction

Data driven production line optimization

Swiss division of Global Pharma

Problem

- Running out of production capacity, significant CapEx investment needed in the new production line to keep up with demand

- Goal: increase the production capacity by 5% via advanced analytics

Solution

- Data integration

- Anomaly detection algorithms

- Data correlations -> insights -> recommendations

Impact

- Trending towards 11% of productivity increase (throughput and yield optimization)

- 15x ROI

AWS Data & Analytics Platform

Multinational Pharmaceutical Company

Designing and implementing a cloud-based data science platform based on AWS (EC2, SageMaker) with Foundry integration to streamline DS use cases

Challenge

- Lacking efficiency of data science projects due to insufficient computing resources

- Heterogeneous and distributed data sources, as well as low data quality

- Regulatory requirements with regard to data integrity

Solution

- Implemented data science platform based on AWS cloud infrastructure and services

- Ensured GxP compliance for regulatory audits of platform

- Established standard processes and procedures to manage and maintain the platform

Business impact

- Increased data science project efficiency due to lower data finding, connection, and preparation efforts

- Availability of modern cloud infrastructure based on AWS including integration with other platforms

- Reduced compliance and regulatory efforts (“compliant out-of-the-box”)

- 5 use cases went live in first 9 months on the platform

Foundry Platform Governance

Multinational Pharmaceutical Company

Designing new governance framework in collaboration with client team to streamline Foundry governance processes across the organisation

Challenge

- 4 semi-independent departments (data-wise) with only one using Foundry

- Current Foundry governance processes not scalable, new centralised “data office” (DO) to take-over organisation-wide governance efforts

- New data office had no Foundry experience

Solution

- Helped engineers in new team onboard on foundry

- Orchestrated upscaling of governance processes and coordinated with other DOs

- Designed new governance processes whenever necessary

Business impact

- Significantly improved governance processes with better access control

- All sector DOs now have access to necessary resources for use cases

- Lower request resolution waiting time thanks to more efficient governance framework

Manufacturing Analytics Platform on AWS

Multinational Pharmaceutical Company

Designed and implemented advanced analytics platform on AWS allowing quicker launch of new projects, faster data access, and better project cost monitoring

Challenge

- Goal to help accelerate development of advanced analytics initiatives in the company

- Environment for quick and compliant project development necessary

- Need help designing and implementing central platform

Solution

- Designed and implemented a shared analytics platform on AWS

- Laid the foundational building blocks, i.e.,:

- Identity & Access Management

- Data Governance & Security

- Development Lifecycle

- Data ingestion, processing & presentation

Business impact

- Reduce time required to start new advanced analytics projects by implementing standard platform

- Reduce time needed to access the right data

- Allowed accurate monitoring of project costs

- 6 projects onboarded within first 3 months

Production Line Optimisation

Multinational Pharmaceutical Company

Increased production line capacity by 11% through data analysis and ML modelling avoiding the need for significant CapEx investment to build new line

Challenge

- Manufacturing line running out of production capacity

- Significant CapEx investment needed to keep up with demand

- Goal to increase production by 5% through advanced analytics only

Solution

- Conducted exploratory data analysis to get good idea of production line and its overall equipment effectiveness (OEE)

- Prioritised most promising actionable levers to increase OEE with domain experts and simulations

- ML modelling, root-cause analysis, anomaly detection & optimisation

- Report detailing approach and gain for each lever

Business impact

- 22 improvement levers investigated in total; 6 retained and 3 implemented

- Improvements implemented led to faster overall production process

- 11% yield improvement

- 200 million extra tablets produced each year → CHF 40+mio in increased revenue

- 15x ROI

HelloML Code/Application Review

Medical Equipment Manufacturer

Evaluating existing MLOps setups and tools used, providing improvement recommendations, and directly implementing some of those recommendations

Challenge

- Needed help in evaluating their MLOps setup that is currently being developed

- Mock data science project to be used by data scientists as an example to follow on future projects

Solution

- Evaluated existing tools and performed suitability assessment for the current and planned use cases

- Implemented some of our recommendations to provide clean split of responsibilities between the tools

- Recommended best practices on how to scale their infrastructure in the future

Business impact

- Significant improvements in existing MLOps setup by challenging status quo and providing recommendations

- Implemented best practices in their mock project example

- Praised by stakeholder for having also implemented things, going beyond mere recommendations

Medical Coding Complexity Prediction with NLP

Swiss Pharmaceutical Company

Developed a machine learning model that predicts the complexity of coding/tagging a stay given the clinical documents to improve billing correctness

Challenge

- Correct tagging of patient stay needed for accurate insurance processing

- Incorrectly tagged documents can be under-reimbursed or rejected

- Some documents are very complex to tag/classify, and others are routine

- Need to know if a document is somehow “off” (i.e. anomalous) from a content perspective

Solution

- Created data pipelines for clean aggregation of data

- Built application to automatically classify the “complexity” of documents, so they would be handled by the correct expert

- Same application created knowledge to enable working on anomaly detection

Business impact

- NLP model accuracy comparable with human expert coders

- Faster tagging for billing purposes

- More efficient workload distribution of coding tasks based on complexity and code skill

- Better decision support and minimised manual errors

MLOps process for ML Model Deployment

Swiss Pharmaceutical Company

Established a common development framework, as well as a standardised release process enabling faster and more efficient ML model deployment

Challenge

- Data Science team at client has been working on several ML projects that need to be put into production

- Goal of this project was to provide an initial MLOps process to deploy models into production

Solution

- Consulting and implementation of right technology stack combined with establishing a proper process

- Established common framework (Kedro) to develop ML models. Setup a standard release process to deploy ML use cases

- Defined tech stack needed for future use cases

Business impact

- Established common development framework to standardise processes

- Best practices put in place for development and release of software/ML models

- Built initial infrastructure enabling reproducible ML pipeline creation on-premise

Telemetry Data Dashboarding

Swiss Biotechnology Company

Building interactive dashboards on PowerBI from telemetry and sales data enabling salesforce and management to derive actionable market and customer insights

Challenge

- Telemetry and sales data have been collected separately but were not linked to deliver business value

- Management and sales representatives were not able to derive business insights as data could not be visualized in real time

Solution

- Built an interactive PowerBI dashboard, aggregating data from various data sources

- Included “smart insight recommendations” based on real time data

- Implemented various filtering options to analyze KPIs based on multiple criteria

Business impact

- Improved decision-making through inclusion of real time data to derive market insights

- Increased sales efforts enabled by better client-specific recommendations

- Generated high level insights allowing management to see things under a different lights

Augmented reality microscope

MedTech company

Implementing computer vision models for a digital microscope scanner with augmented reality features

Problem

- Product development of a digital microscope scanner with augmented reality features

- Delineations need to be created around areas of cancerogenous cells

- High resolution images (1px = 2 micron, 400 Mpix)

- Delineations ready below 5 secs

Solution

- Pixel-wise predictions

- Choice of hardware and software architecture for the inference

Impact

- AI contribution to the product development (TensorFlow, Keras, ConvNets, fully-convolutional network)

Patient data classification

US pharma producer

Problem

- Difficulties to identify the patients eligible for the particular treatment, based on narrow criteria in the free text patient records

Solution

- PoC to create a way to look up patients meeting the particular criteria using pattern matching and machine learning so that they can be qualified for treatment

Impact

- The eligible patients will receive the treatment they are eligible for

- Time saving compared to a manual lookup

Production line continuous monitoring

Swiss division of a Global Pharma

Problem

- The customer’s production line went through a data driven optimization, the customer wants to ensure the production line maintains the highest possible OEE and wants to add advanced features like automated issue detection & prediction

Solution

- Near real time continuous monitoring system of key production processes with advanced analytics built in (alerting, trend detection, anomaly detection, predictive maintenance)

Impact

- Greater production process visibility

- Quicker time to resolution

- Improved uptime

Production line optimization

Swiss division of Global Pharma

Problem

- Running out of production capacity, significant CapEx investment needed in the new production line to keep up with demand

- Goal: increase the production capacity by 5% via advanced analytics

Solution

- Data integration, AWS platform

- Anomaly detection algorithms

- Data correlations -> insights -> recommendations

Impact

- Trending towards 11% of productivity increase (throughput and yield optimization)

- 15x ROI